If you’re fitting a new waterblock to your PC, such as the one we’ve used in or guide on p100, then you’ll want to consider using liquid metal thermal paste between the CPU heat spreader and the block’s contact plate. The liquid metal paste is highly thermally conductive, which means that you can get the most out of your water-cooling system and knock a few extra degrees off your CPU temperature compared with normal ceramic paste as well.

Dealing with liquid metal paste isn’t easy, though, and it needs some attention – unlike ceramic paste, you can’t rely on the force from your cooler’s mounting system to spread the paste evenly. However, once you’ve mastered its application, you can rest assured that you’re using the very best thermal paste you can buy, and then enjoy watching your CPU temperatures drop.

Remove Old Paste And Clean Surfaces

It’s vital to remove any old paste first, so clean the surface of your CPU’s heat spreader with TIM cleaner and a lint-free cloth to ensure the new paste works as well as possible. You’ll also need to clean the contact plate of your CPU if it’s been used previously.

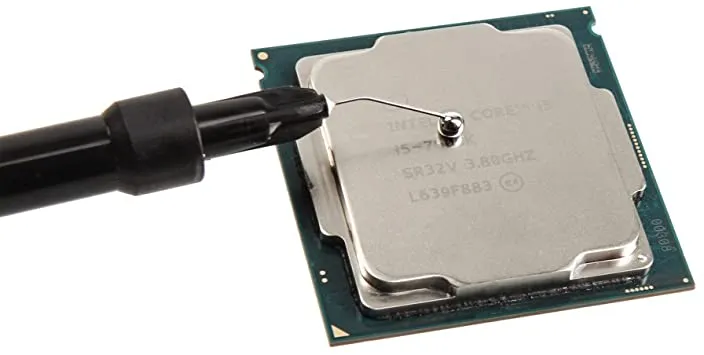

Apply Liquid Metal Paste

Using the right amount of liquid metal paste is important. It’s expensive, so you don’t want to waste it and you only need a small amount to cover even the largest CPUs. Aim for a blob that’s the size grain of rice – if you apply more by accident, you can use the syringe to suck up the excess.

Rub Into Surface

The Thermal Grizzly Conductonaut paste we used includes buds to rub the compound into the heat spreader. This can take a few minutes as the particles begin to adhere to the surface, but eventually, the paste will turn the surface mirror silver. Ensure you cover the entire heat spreader and you’re then ready to fit your cooler.